Process

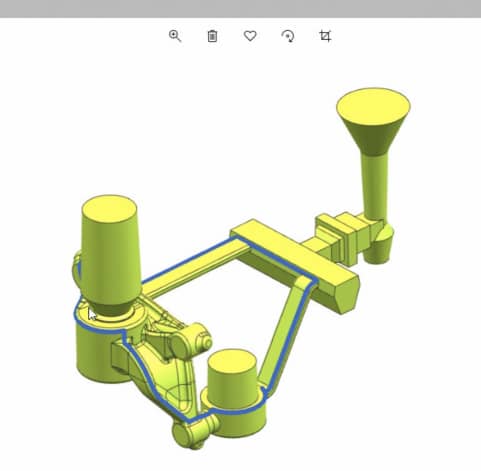

Equipment

Protecting our environment

80% of our materials is derived from recycled materials

Quality

URKOASE carries out comprehensive quality control of our various manufacturing processes: receipt of raw materials, processing, treatment, etc. to certify product quality under standard UNE-EN 10204 3.1.

We have Lloyd’s Register Bronze Foundry certification.

We can also subcontract the analysis and assays to external laboratories (AZTERLAN, SCI, etc.) to certify the material under standard UNE-EN 10204 3.2.

R, D & I

URKOASE understands that technological development and innovation are indispensable for providing an offer with differentiated value that ensures market relevance.

We currently collaborate with the IK4 AZTERLAN technology centre to identify new materials that allow us to widen our offer, optimise our production processes, and promote the circular economy model.